What to write in a tech pack

So the past couple of blogs have been about keeping track of fabrics and trims and costing a bra. This piece covers what to write in a tech pack, it’s one of the most common questions I receive.

Going from a design in your head, to an actual sample to getting lingerie manufactured is where most people come to a dead end. Most factories, can’t or won’t give you a price unless they receive a tech pack or at least a construction page, how they they cost a bra you’ve designed unless they know the exact sewing procedures you are wanting. How complicated your design, or fabrics you are using will determine how long it takes to go through production.

By presenting a tech pack or page, you look like you understand how everything works, you look professional and it saves the factory time and you’re more likely to get an answer as factories deal with many requests from designers approaching them to get their lingerie made up.

So what to write in at tech pack?

A lingerie tech pack is similar to a fashion design tech pack, apart from you would have more on your trim page, elastics underwires etc.

Through out my years designing I have presented my tech pack the same, the only difference being is if I’ve worked for a company that manufactures in China, and they are printing and designing their labels and garment labels, then I would have an extra page for that, including artwork that they need. But usually I would start off with a summary page which includes an overview of the garment, the size range and a check list of everything you are sending to the factory with a comment box (for you or them to write in) so you may be sending patterns, a spec sheet, a check box for when they send you Pre-production samples etc.

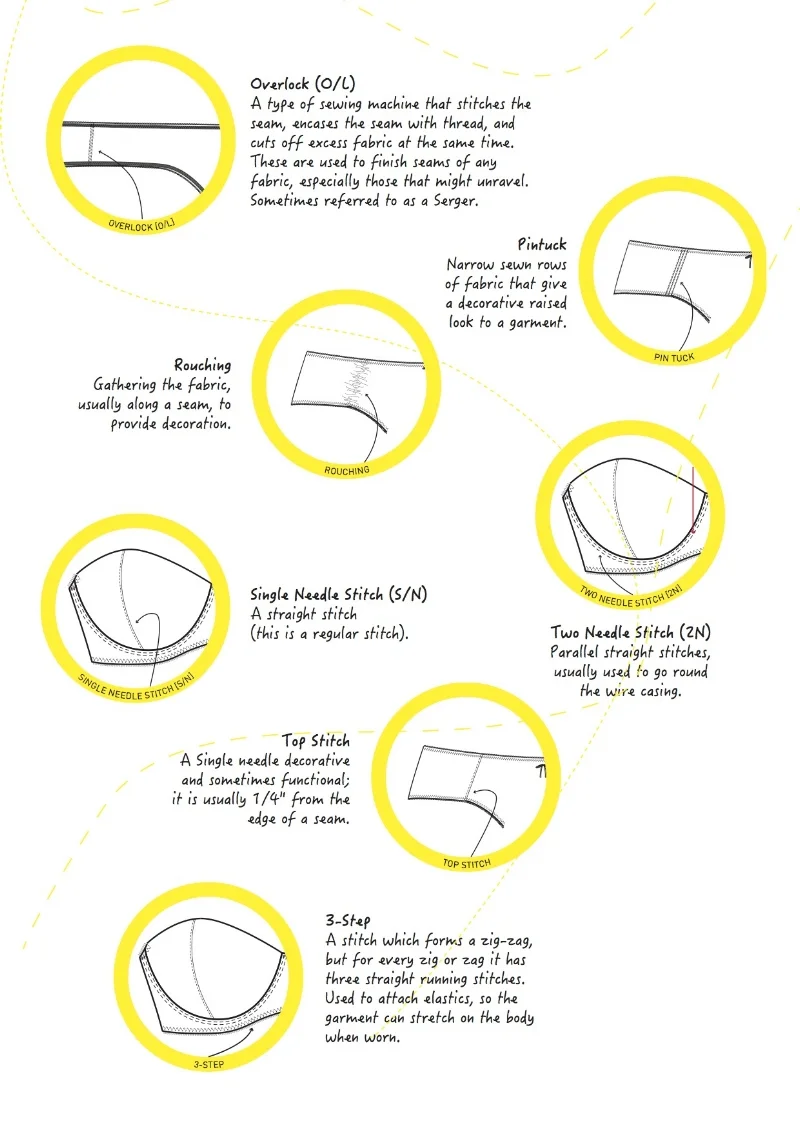

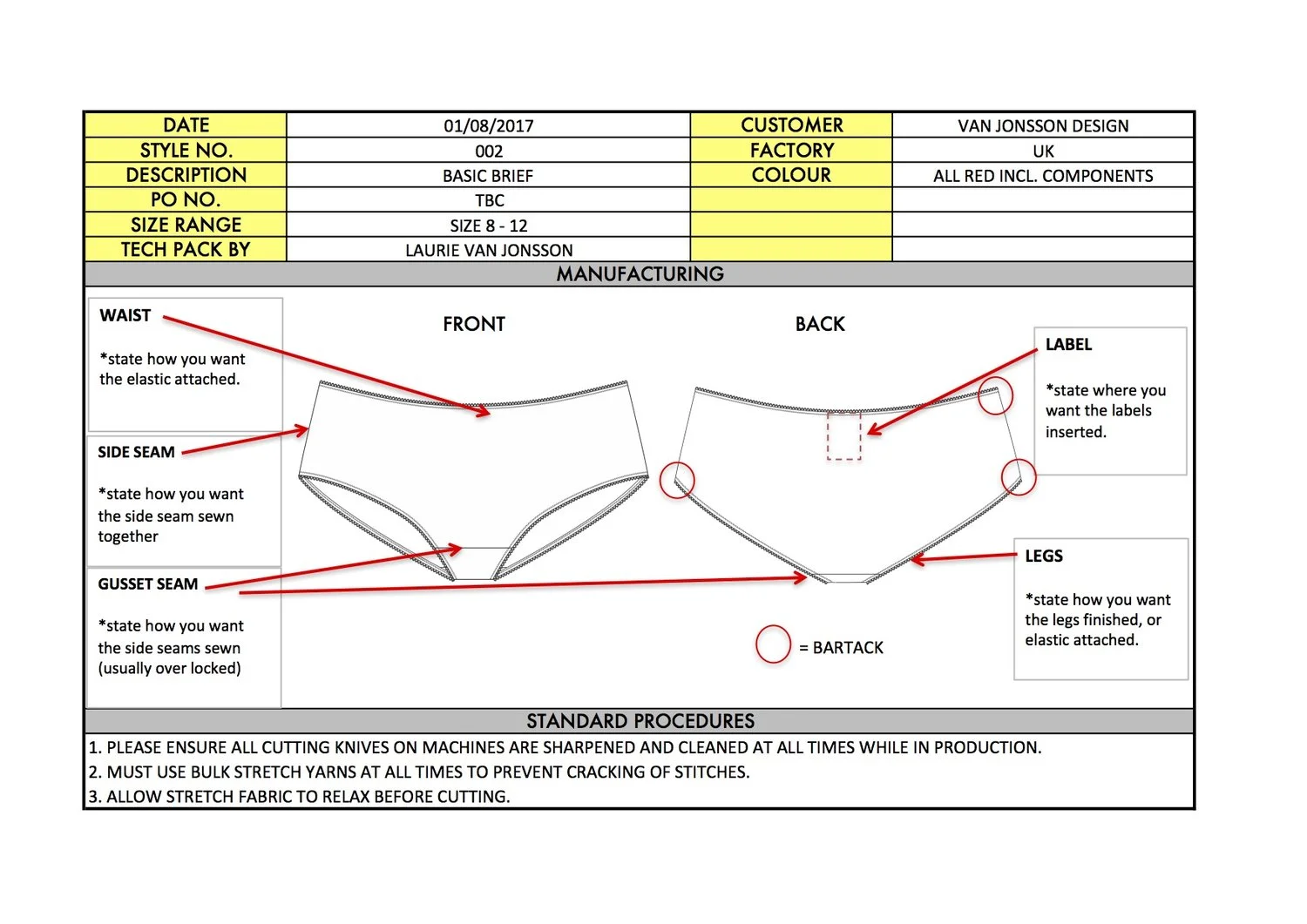

A construction page is the most important, the more detailed this is, then mistakes are less likely to made. Every sewing procedure will be added, so every seam, where the label goes, and how it is sewn, a running stitch? A zig -zag stitch? Twin needle?

*This is an extract of “How to write a tech pack for a bra and brief”

After the construction page, you will usually have a trims/fabric page, depending on the amount of detail of the construction page, this can go on the same page as the construction page, but usually with lingerie you can have over nine components not including fabrics so it’s sometimes easier to put it on a separate page for space.

Either the trims I note down everything so when I look back I know everything about that design of lingerie. For example I would note down the article/reference number (so I can order it again) composition (what it’s made from) and placement (where’s it is on the garment). And with the fabric I note down the fibre content (what it’s made from).

This may be enough in your tech pack, other pages to add would be about the labels, the sew in labels and the swing labels, this is important to add if you’re getting your factory to source and produce your labels, you would need to send the artwork to them and the details such as the washing instructions on them.

Also if you’re getting your lingerie shipped from far away you need to think how it will be packed, if you’re an eco-friendly brand you may not want it shipped in plastic etc.

if you have no preferences of how it is packed then don’t worry, your chosen factory will have experience of shipping lingerie so will pack it safely.

When I first got a factory to make Vanjo it was the factory in Wales (AJM) , I visited the factory first and took my sample then sat with the sample machinist and talked her through how I wanted the sample to be, from this she took her own notes with what machine she used and what tension and size the stitch should be so it could go through the factory the same.

If you’re at a complete stand still on how your garment should be made I recommend starting to look at the inside of lingerie and see what stitches they have used, and if you want more understanding check out this book.