How to cost a bra and brief

When I first started out Vanjo I was a little bit bewildered about the costing side. I only had costed for big companies, where I either knew what each operation of sewing costed therefore could reduce costs with buyers if needs be or companies had their own formula whereby you would enter what the bra and brief cost and the calculations would happen then you could adjust accordingly and get them signed off.

But there I was about to launch my own label and I didn’t know where to pitch my prices, it all seemed different for your own brand, of course there was the actual costs to add in, but what about everything else. I contacted my friend who at the time had her lingerie label stocked in Liberty and she told me that not only are you proving lingerie but you’re providing a fit, and to pitch yourself at your customer, again we go back to your customer base.

If you’re designing a high end lingerie label, your fabrics are going to reflect that and your prices, don’t just pitch high in hope that you are that high end brand, you have to execute it all.

I wasn’t aiming for the high end lingerie brands, my label was to help women find a good fitting bra with small backs and big brands. I didn’t use the most expensive lace, but I used french lace, so not the cheapest either.

I wanted my brand to be able to expand, so from the start I added in manufacturing prices, I know that going wholesale I would wouldn’t make much profit, but by going wholesale I could then meet minimums on my lingerie, and be able to offer my lingerie to stores and not worry about making them. Although truth be told, I only did one factory run and the rest I handmade, but my having the manufacturing price already in meant that I didn’t have to raise prices for the lingerie at a later date.

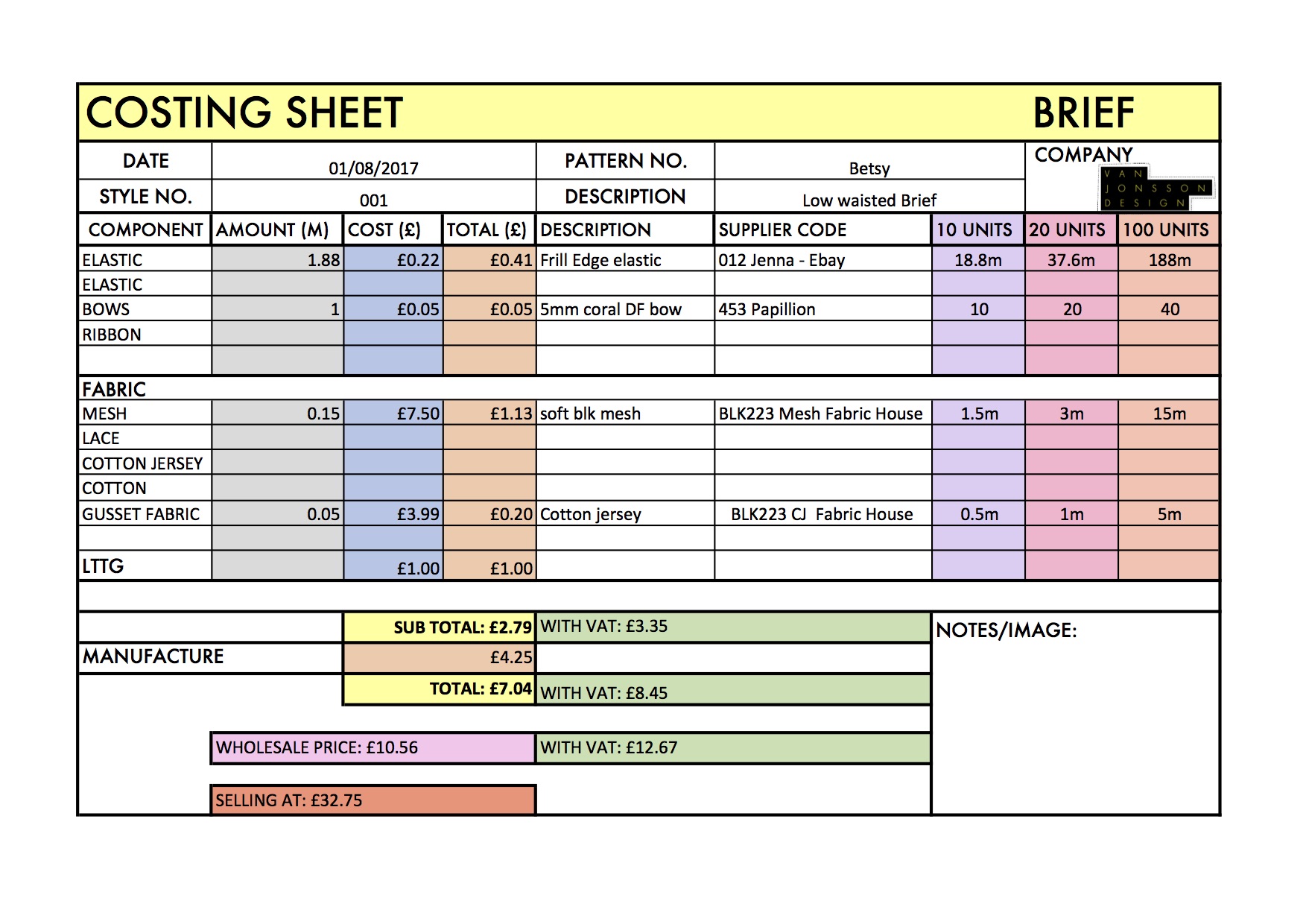

Below is an example of a basic costing sheet with the direct costs (not the indirect costs), and example of the bra costing sheet, and blank costing sheets and instructions how to work it all out can be found on the designs sheets in the shop section.

So we all know that without profit and cashflow you have no business.

A basic cost would be : Costs of fabrics + trims + labour + business overheads + profit = Garment costs

After deducting all of your direct and indirect costs (such as rent in your studio) you are left with your profit.

Things to take into consideration when costing are direct costs and indirect costs (your overheads), your hurdle rate (how much profit you need to make ) what your competitors are charging ie where do you want to position yourself in the market and what the customer is willing to pay (what benefit are they paying for when they buy from you.

Before you begin costing you will need to know how much fabric and trims does one garment make then you can work out the percentage of the cost. Just be aware of unseen costs like post costs.

If for example a bra costs (with the pattern and graded) £120 and you’re only selling one then you will have to factor in the full £120 but if you’re planning to sell six then 120/6 = 20 then you factor in this price, and if you’re planning on using this pattern again and again then the price shall be even lower.

You can also work backwards, if you know your market your aiming for sells say bras at £125 and you;re marking up at 2.5 then you can work out the whole sale price (£50) then if you’re wanting to make 2.5 you then know that the bra needs to be made at £20 to get the figures correct.

Remember mark-ups and margin are two very different things. Also another to know is Gross profit is Selling price - Direct costs.

And Net profit is gross profit - Indirect costs

Net profit is usually the money you pump back into the business to get it going.

And I’ll say it again, if you have no cash flow or profit you don’t have a business.

An automatic cost sheet can be found below