Lingerie production terms you may need to know

When you’re discussing with a factory about your lingerie design, you may need to know the following terms so you understand what they are on about.

BULK: This means your final order, you may hear the term “go/approved to bulk” which means that you have signed off on the sample (confirmed that the sample is correct and you are pleased with it) and you are ready to proceed and commit to the order being manufactured.

CAD: Computer Aided Design - your design drawn up via a computer as a concept of your idea.

CALL OUT: This is a special instruction about your design, so as well as mentioning it in your tech pack, you may well have it repeated it on the spec or style sheet. For example ‘please ensure that the darts aren’t pointy ‘

CMT: This is literally what it stands for, which is Cut Make Trim, which involves the factory cutting the fabric (CUT), sewing the lingerie (MAKE), and trimming the lingerie before packing it for delivery (TRIM). Basically any quote from the factory for this means that they are not providing fabric or trims, and you have to source and provide that.

CRITICAL PATH: This is the order that everything is done, from lab dips to samples to grading. Even though the factory should keep on time, it’s your job to ensure this, and contacting them if the time starts to slip. (This is something that the lingeri-e-course will cover).

DIGITAL PATTERN: This is the same as your paper pattern except on computer.

DTM: Stands for Dyed to match

EX-FACTORY: This is the date that your lingerie leaves the factory. If you are sourcing form China this is not the date that it gets shipped, it has to get from the factory to the port, so bare this in mind if you are booking freight space.

FLAT SKETCHES: This is a technical drawing of your lingerie drawn flat which includes, style and stitch lines.

FOB: Stands for Free on board, which is term for shipping on who pays what deliver and what insurance for your lingerie to arrive to you. This will be on your quote from factories. FOB stands for that cost of transport to the port is covered, as well as manufacturing and sometimes in some factories fabrics as well. There is a full list of Incoterms (list is in How to be a Lingerie designer) that can be found on internet. I would clarify with the factory what is included as each factory can have a different interpretation of what it means to them.

GRADING: Taking your original pattern to different sizes.

LAB DIPS: Colour swatches of fabrics and trims sent to you to confirm that the colour is correct. You usually receive more than one. If you haven’t a light box, look at these samples inside and outside to get different perspective of lights.

LEAD TIMES: This is the time the factory quotes for your lingerie to made and is the date that it is leaving their factory.

LINE SHEET: This a basic document consisting of one sheet of paper, that includes styles, design images, available sizes, colours, fabrics and any other specification of your lingerie. This is presented to buyers for them to buy from. So if you are getting orders before production this is a crucial piece to have.

MARKERS: This is a layout of all your pattern pieces on paper which will be cut from the fabric for production.

MOQ: Stands for Minimum Order Quantity, if they minimums are too high for you, you can usually get round this by paying a surcharge but this will have a big impact on your costing.

POM: Stands for Point Of Measurement, where you want the factory to exactly measure your lingerie.

PP: Stands for Pre-production sample, this is a sample made before production to check everything is okay, once this is approved production can start (they can go to bulk).

SIZE SAMPLES: Production sews each size to ensure all the patterns fit together (this is also discuss in the lingeir-e-course).

TOL: Stands for Tolerance, which on the spec sheet shows how much you are going to tolerate the lingerie measuring bigger or smaller. For example if the top of the cup states 12cm and the tolerance is 0.5cm then you would accept garments that measure 11.5cm or 12.5cm, anything over than that then you need to speak to the factory about how it can be put right.

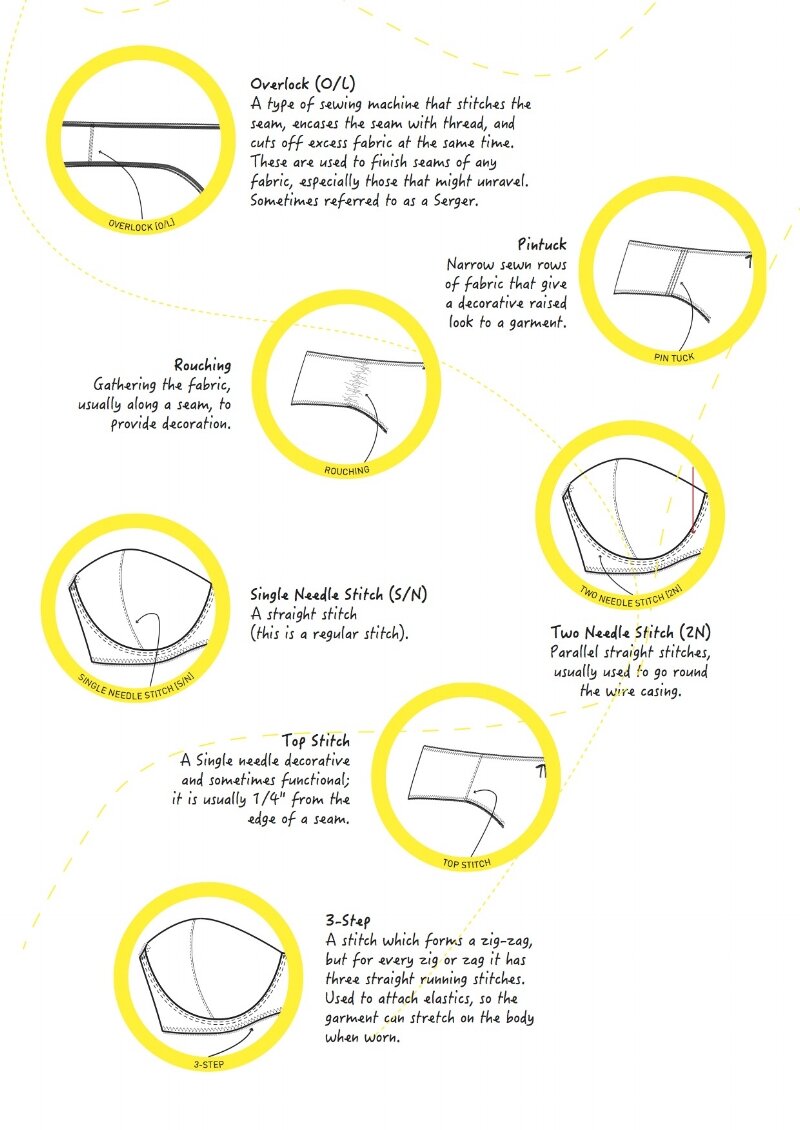

If you want to know more about sewing terms then this is a page from “how to write a tech pack for a bra and brief”