Thirteen steps to planning out your lingerie range

Where to start? You have an idea or design in your head, or mapped out and a sample staring you in the face, but where to go from here? And what about next season’s range?

Should you start that as well or be thinking about your first range?

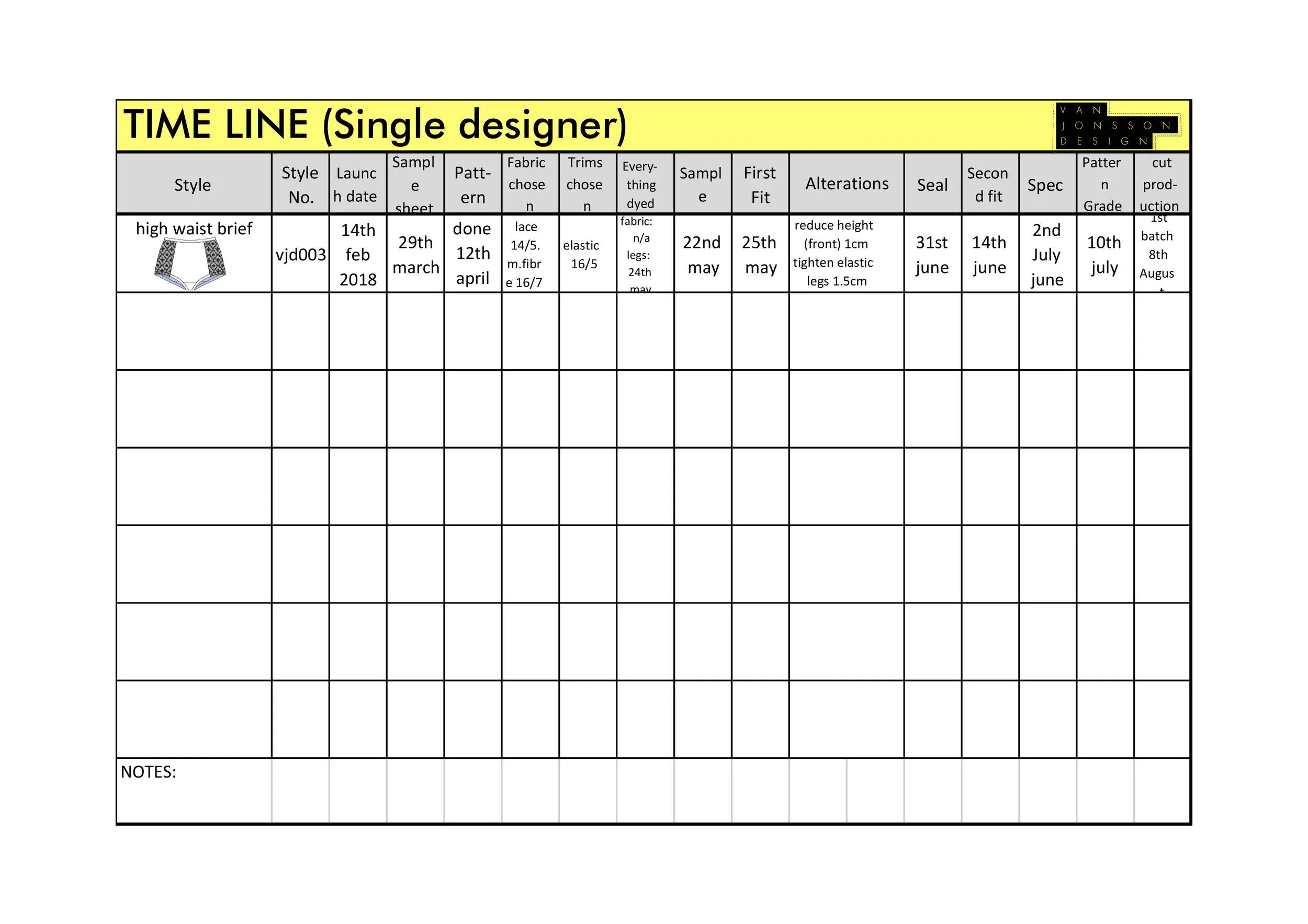

So many questions it can be confusing and time stressful to fit everything in. So I’m going to go through each stage of what it takes to get from idea to manufacturing, feel free to dip in at any point that you are along the time line.

I will do an example if you were making it all yourself, obviously this would be different if you were getting the samples and production outsourced by a lingerie manufacturer.

This time line with further examples and blank sheets is available to buy in the design sheets

Let’s begin..

The design - have you finalised your design? Including fabrics and the sizes you are going to be covered.

When do you plan to launch? This is important to know - it may get put back, as things often take longer than you would like, especially in the start, but if you can begin to work towards a date, it’ll be easier for your next collection and you can then work backwards, deciding when you need to get things done by.

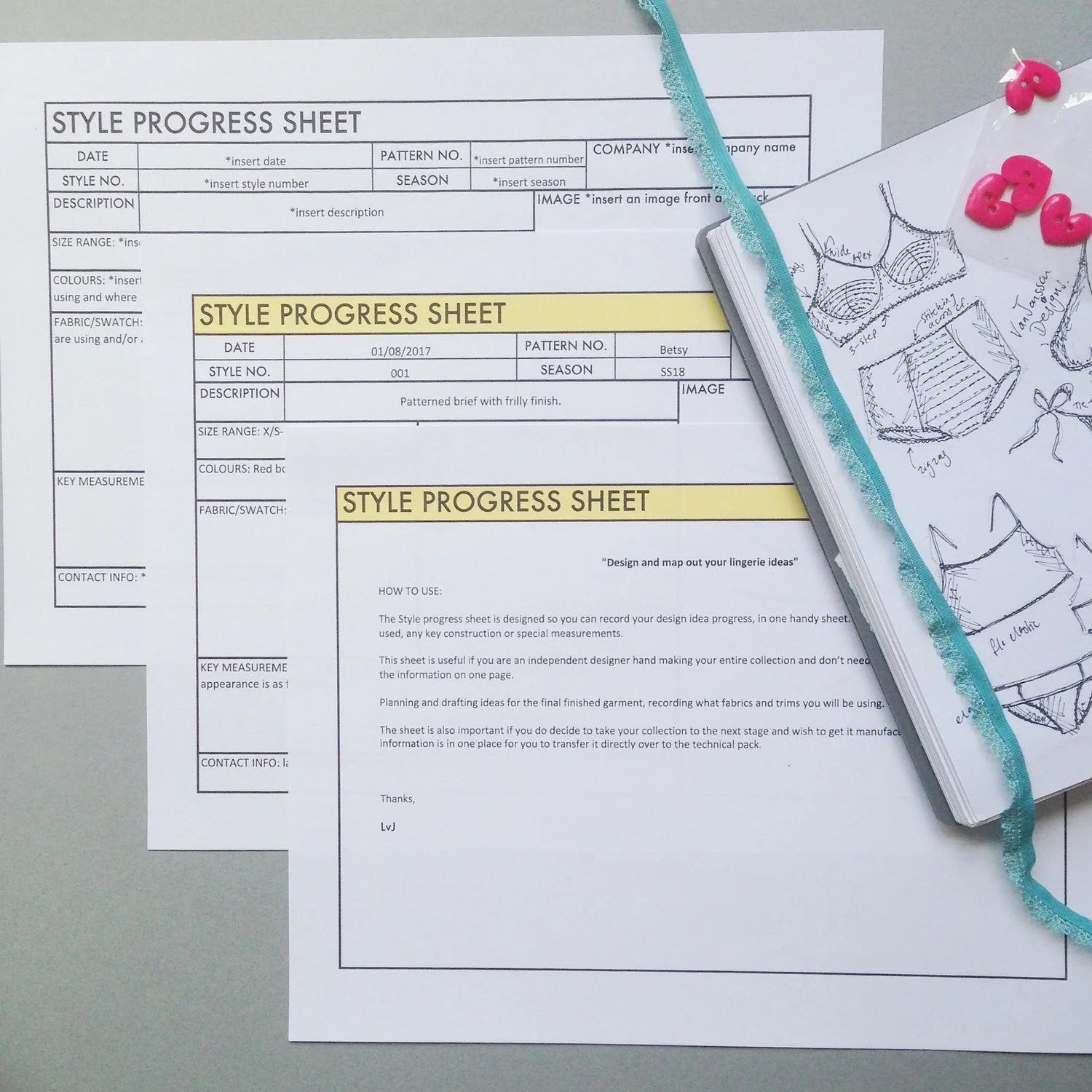

Sample sheet/style progress sheet: I think this is great place to get everything down in one place. How often are you flipping through a notebook looking for information on your designs, by separating each design onto it’s own page, you begin to jot down notes, on fabrics, trims, styles, and what you else you need. I would then duplicate this when you have all the correct information.

This progress style sheet is available to buy in the same pack as the time line

4. If you’re doing the sewing yourself then you don’t need to get a technical drawing done as it’s only you that needs to understand how you’re sewing it up. So next you need to think about Patterns, are you going to outsource these or are you going to do them yourself.

5. Fabrics: Have you ordered any for sampling? If you are ordering online have you asked about how much they have? I’ve have fallen victim before to ordering 1 meter of fabric loving it , getting all my samples signed off, only then to discover that the fabric isn’t available anymore. You can either buy more than your sampling if you know that, that’s definitely the fabric you want. If you’re dealing with fabric manufacturers then they should be able to knit you more but there will be a minimum, if you’re buying online then check the quantity. This is where knowing your launch date is important because you know exactly when you need to have the fabrics by.

6. Trims: Basically the same as fabrics, though harder in some aspects as you need to make sure you have everything: elastics, (maybe more than one style), rings and slides, hook and eyes, and strapping.

7. Are you planning on dying everything, or buying black, white or notions already dyed?

8. Right sample time: if you’re making it then you should have your fabric sampling, you don’t need to make your sample in the correct fabric to start with if you want to see if you’re pattern works. However I recommend making it in the correct fabric and trims for your fit first, as you get more efficient with this, by all means pick similar stretch fabrics. This is the joy of designing lingerie rather than outer wear, you’re not having to outlay loads of money for meters of fabrics.

9. Fitting: Time to fit the lingerie - don’t be dismayed if it doesn’t fit at this stage the way you want . Expect one-to-two fitting sessions at least, but if you’re getting to your fourth fit and don’t seem any more forward, start to question your design or fabric choice. Unless it’s a tricky design fitting for the larger cup market or something you have your heart set on, it may kill your soul with the constant fits.

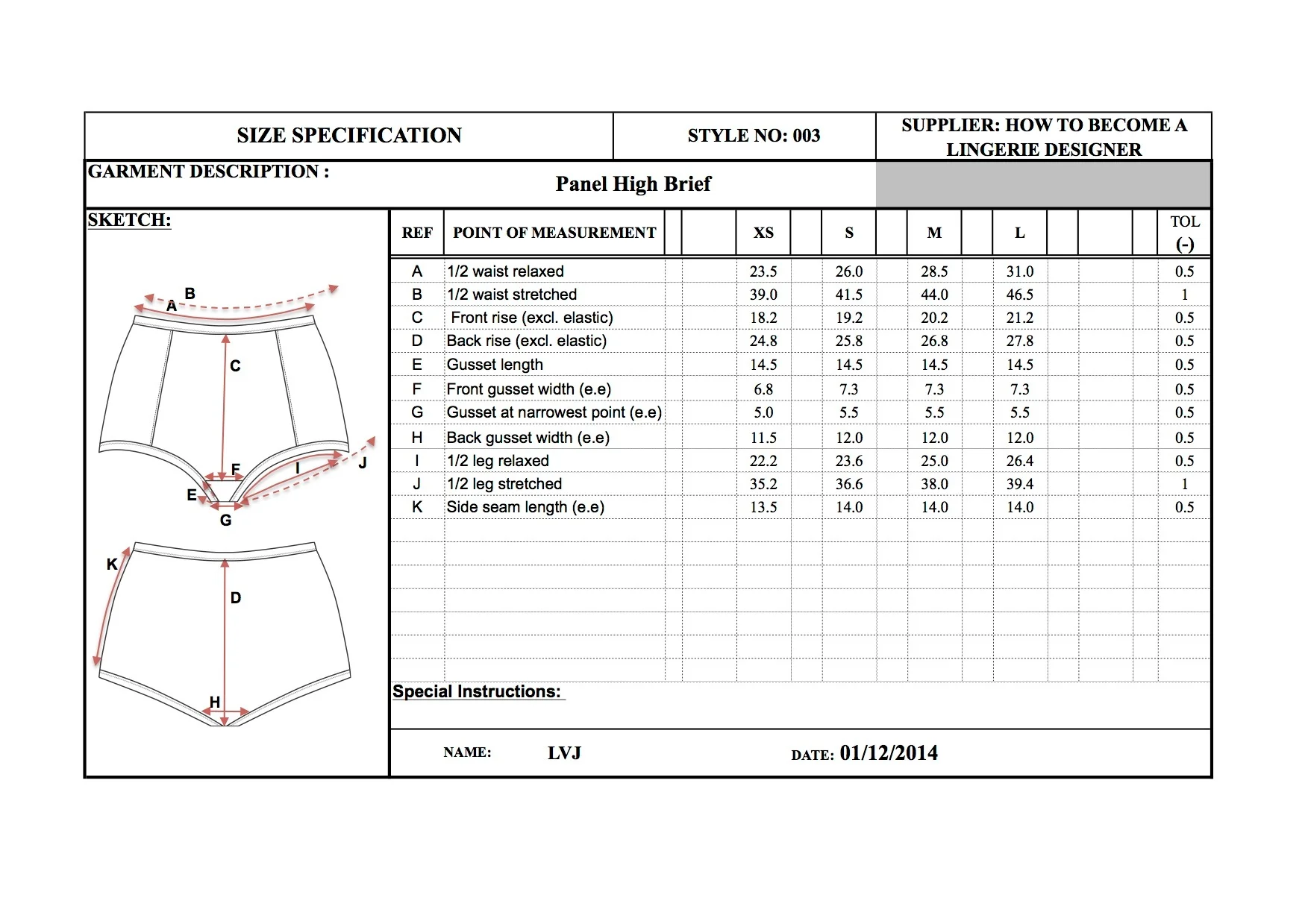

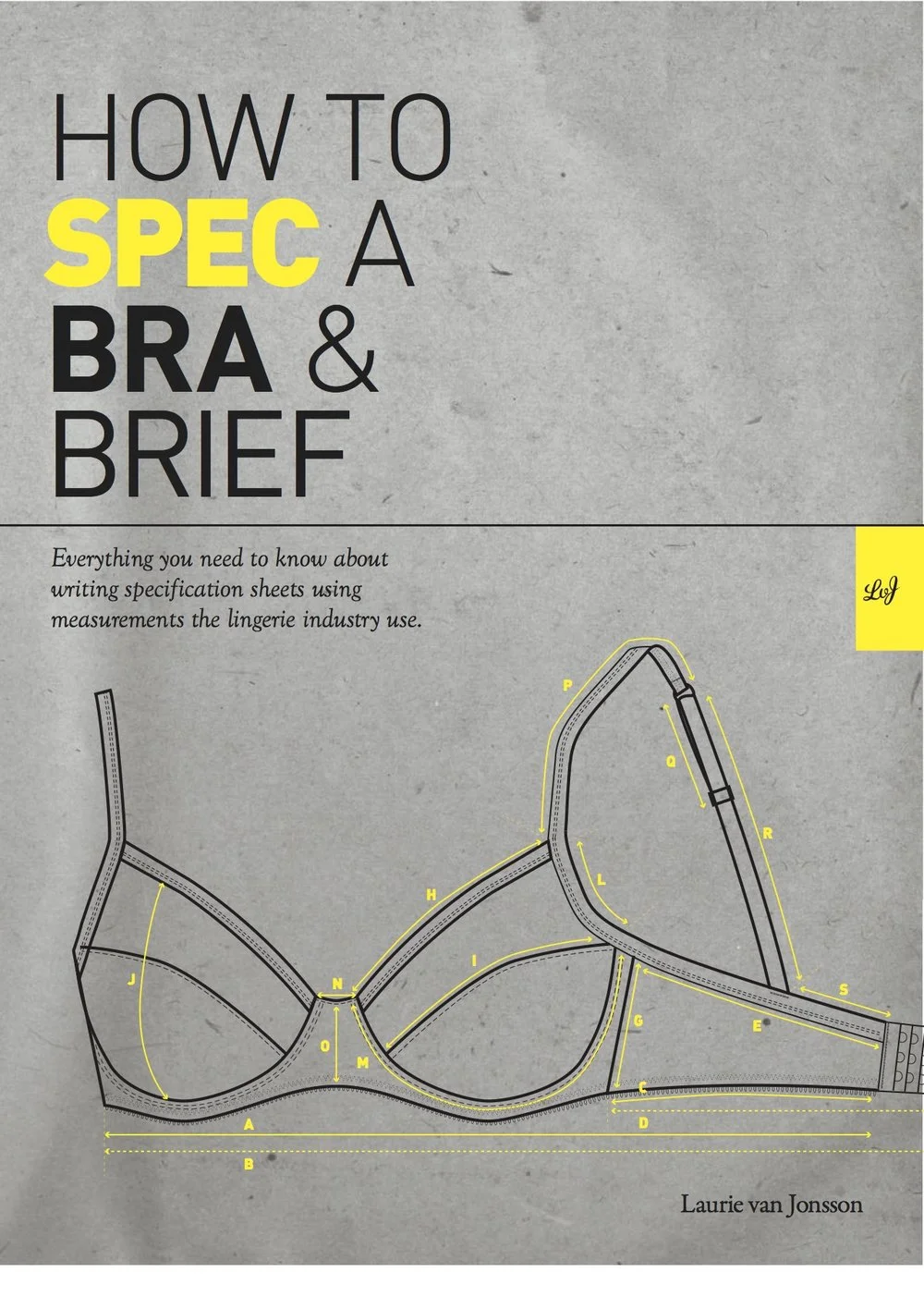

Example of a spec sheet, a blank version and tips to fill one out can be found under the design sheets

A book for those who wish to learn about writing their own specification sheet for their lingerie

10. Seal: This is your final garment with everything correct, how it will fit, the correct fabrics and trims, this will be the sample you refer to when you need to know what is stitched where and how. (any extra fits are put after this as you may not need this column.

11. Specification sheet : This is the sheet with all the measurements you need to make your lingerie in different sizes, it’s also so when you make your lingerie you can check against it to make sure it all measures correctly. Decide whether you’re going to do this yourself outsource it.

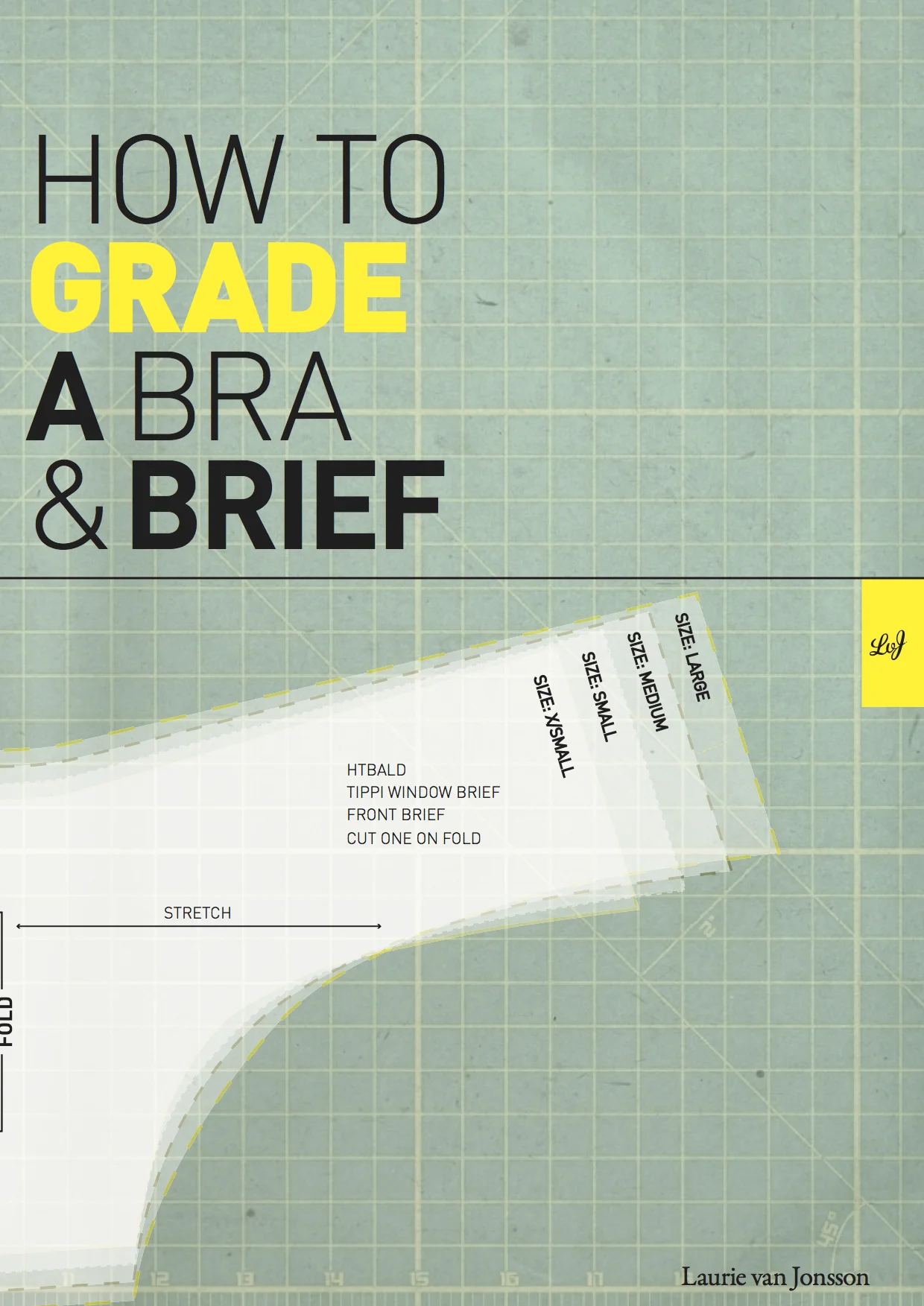

12. Grade your pattern: If you’ve got your designed all signed off, then it’s time to grade the pattern to all your sizes. Having the spec sheet done, you will be able to see how much each part of the pattern needs grading by. Again you need to make the choice whether you are going to outsource this or do it yourself.

For those wanting to grade their own lingerie a book is available.

13. All done !! Now it’s time to cut your production and start to get it made.